Welding Engineering

Ensuring welding quality through design support, qualifications, and compliant fabrication.

Welding Engineering Expertise for Design, Quality, and Innovation

The Welding Engineering team provides expertise in both technical and normative aspects of welding. With knowledge of materials, processes, and standards, the team supports design and procurement, prepares specifications for subcontracted work, and provides technical guidance. It also manages documentation, qualifies welders, and contributes to R&D to advance joining techniques

Expertise in welding processes

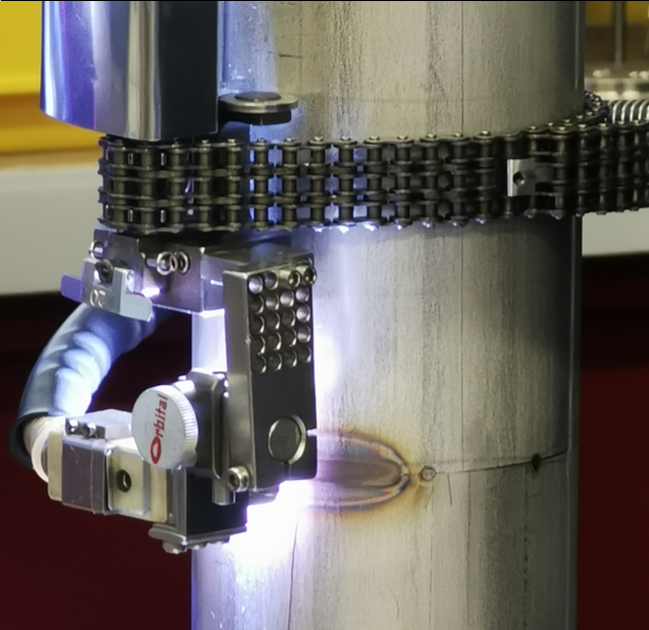

Welding engineers apply multiple welding processes and develop optimized solutions for each specific applications at CERN.

Welding engineers apply a wide range of joining processes—including TIG, MIG/MAG, EBW, LBW, vacuum brazing, orbital, manual, and robotic welding—each chosen for material compatibility, joint design, and service conditions. Their work includes R&D to explore new technologies, optimize parameters, and refine fabrication methods for complex components in high-energy physics. The results are applied to demanding applications such as cryogenic equipment, UHV components, and pressure equipment, where cleanliness, leak tightness, and mechanical performance are critical, and are also transferred to industry through technical documentation and collaborations.

Ensuring Welding Quality and Compliance

Compliance with CERN and international standards is ensured through validated procedures, certified personnel, and systematic inspections

The Welding Engineering team ensures that all activities comply with international standards and CERN’s own specifications. Welding procedures and personnel qualifications are formally approved in collaboration with external certification bodies, while specific CERN requirements are addressed through dedicated qualification processes and inspections coordinated with the Materials Engineering team. This framework guarantees reliable, traceable, and safe welded assemblies across all projects.

Design to Fabrication support

The team provides design-to-production integration, ensuring manufacturability and supporting internal and external welding operations.

The Welding Engineering team at CERN acts as an interface between design and production, ensuring welding constraints and manufacturing realities are addressed from the outset. Working with design offices, they translate requirements into feasible, standards-compliant solutions adapted to geometries, materials, and workshop capabilities. When processes cannot be carried out in the workshop, the team also brings expertise in subcontracting joining processes to industry. Based in the workshop, they test and validate welding solutions, providing feedback to refine processes and align design intent with production

Manufacturing follow-up

Manufacturing follow-up guarantees quality and full traceability throughout production by managing documentation, welding activities, inspections and testing.

Manufacturing follow-up ensures that each step of production meets CERN’s quality standards. It begins with reviewing technical documentation and verifying material certificates for full traceability. The team manages welding documentation and qualifications, oversees operations to confirm compliance with design requirements, and defines inspection needs while coordinating non-destructive testing with CERN’s specialist services.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Forming and Welding Section can do for you.