Vacuum brazing and Heat treatment

High-Precision Bonds in the Cleanest Environments

Expertise in Vacuum Furnace Solutions

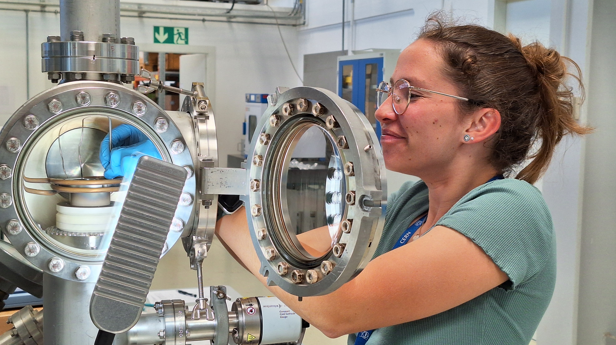

High-Precision Assembly Solutions for Large Scientific Instruments

CERN’s vacuum brazing capabilities combine precise temperature control with advanced joining techniques to produce high-accuracy, low-deformation assemblies. From metals to ceramics, these processes enable complex, reliable components for cutting-edge accelerator and experimental systems.

Vacuum Brazing: Accuracy through Temperature Control

Brazing is the joining of components with a filler metal that melts at a lower temperature than the base materials. Vacuum brazing is a joining process where parts are heated uniformly in a controlled atmosphere. This homogeneous temperature rise enables the assembly of components with high dimensional accuracy and minimal deformation. It is particularly useful for materials that cannot be welded by conventional methods, including metals and ceramics. The process also offers design flexibility, making it possible to produce both simple and complex assemblies, whether in a single operation or through multiple successive steps.

Core Vacuum Furnace Capabilities

A Long Tradition of Precision Brazing Serving Generations of Experiments

With decades of experience in brazing, CERN has developed and refined techniques to assemble complex accelerator components. This long-standing know-how continues to support today’s projects while evolving to meet the demands of future scientific instruments

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Forming and Welding Section can do for you.