Laser Beam Technologies

Shaping Metals with Beams of Light

Advanced laser beam technologies for welding, cutting, additive manufacturing and engraving at CERN

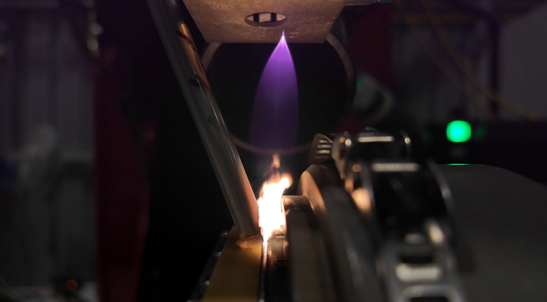

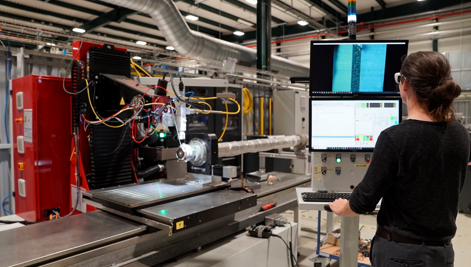

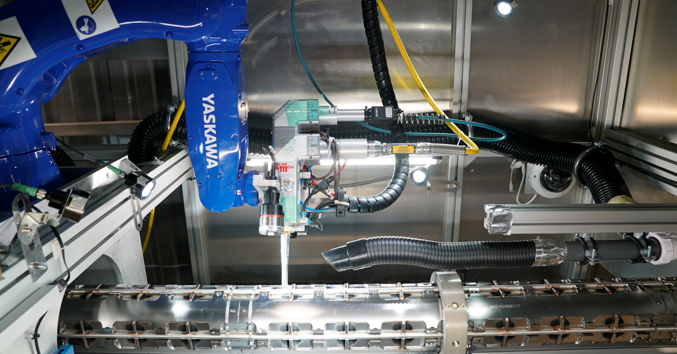

As part of CERN’s advanced manufacturing capabilities, laser beam welding is employed whenever precision, flexibility, and minimal thermal distortion are essential. Laser welding allows joining with extreme accuracy, down to the micro-scale, while maintaining high repeatability and surface quality. At the other end of the spectrum, large assemblies such as beam screens and accelerator components benefit from automation and CERN’s dedicated Class 4 laser workshops, which enable the processing of very large parts.

Beyond welding, lasers are also used for cutting, additive manufacturing, and engraving, providing a uniquely versatile toolbox for tackling both delicate prototypes and large structures. These processes can be finely tuned by adjusting beam parameters, optics, and scanning strategies, ensuring reliability and reproducibility across diverse applications.

With decades of experience, CERN continues to refine and expand its laser capabilities to meet the demanding requirements of high-energy physics.

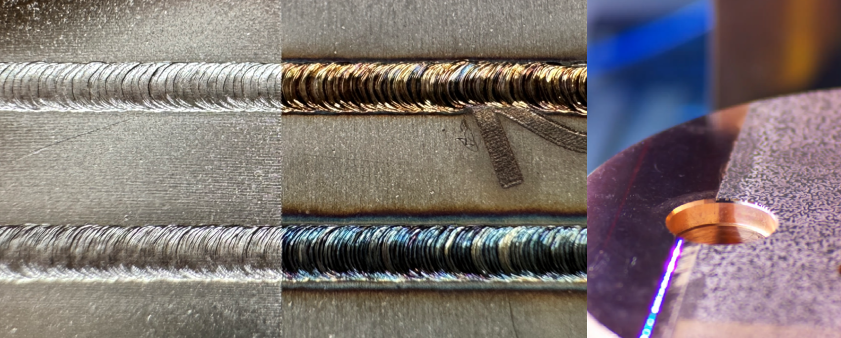

Laser Welding

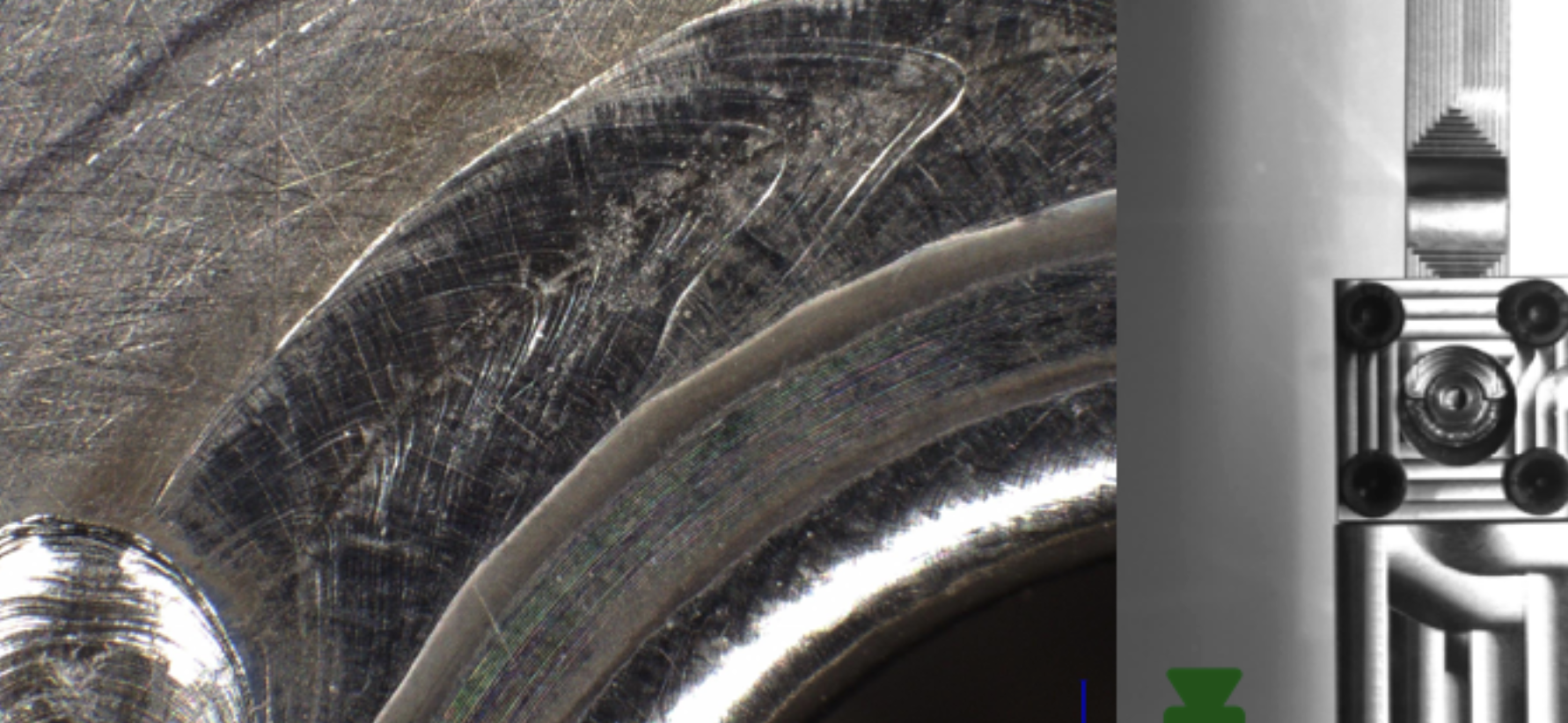

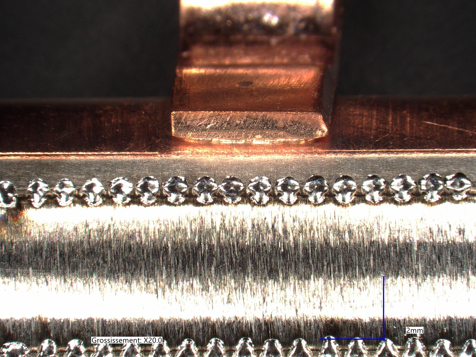

At CERN, laser welding is primarily applied to stainless steel, offering exceptional precision across scales — from delicate micro-welds to large assemblies. This versatility ensures reliable joints with minimal distortion, supporting both prototype development and high-volume fabrication of accelerator components.

Additive Manufacturing

Metal additive manufacturing makes use of widely available alloys such as titanium and stainless steel 316L, while also advancing the processing of materials of special interest to high-energy physics, including niobium and tantalum. This enables the production of complex geometries and the development of novel components for demanding applications. Know more.

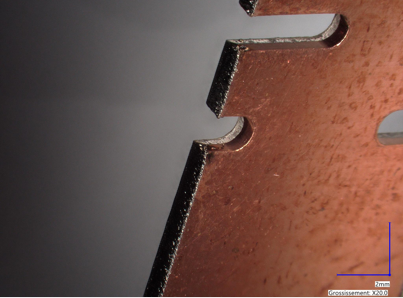

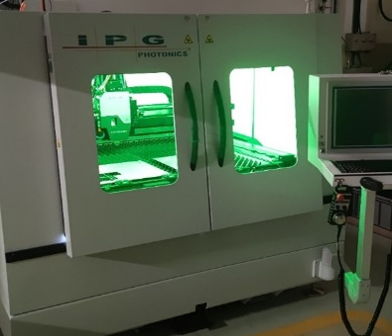

Laser cutting

Laser cutting offers high precision and flexibility for sheet formats exceeding one square metre, as well as the capability for complex 3D geometries. The process can also be applied to fragile materials such as wafers and ceramics, enabling delicate and accurate shaping.

Laser Engraving

Laser engraving provides high-precision marking and deep engraving on all metals. The process also allows cutting of thin foils, from 0.2 mm down to a few micrometres, and can perform controlled laser cleaning of delicate surfaces.

Facilities

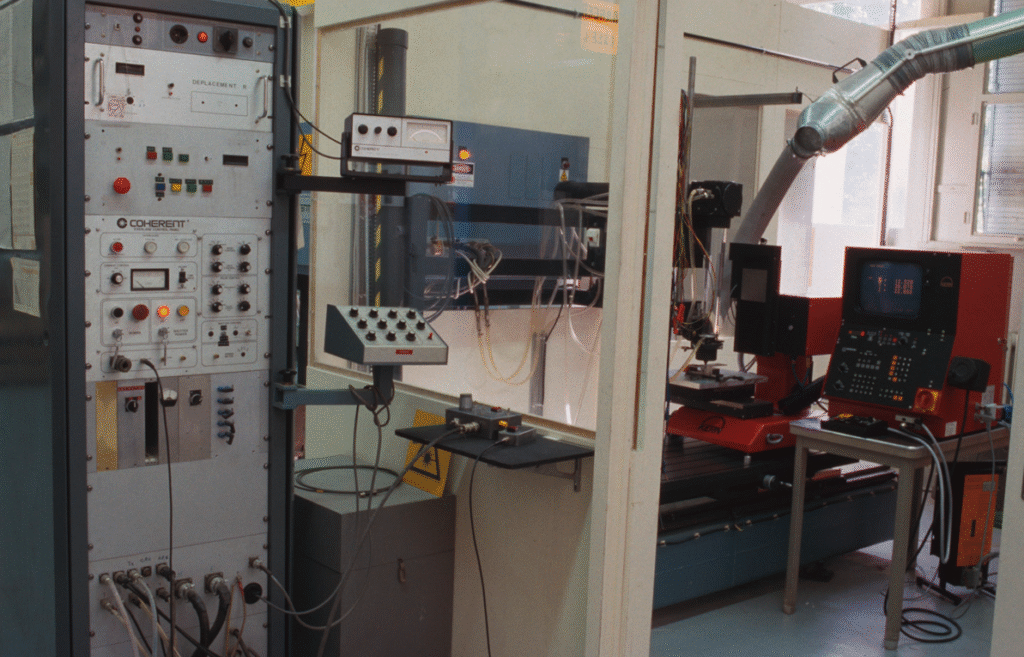

Our workshop is equipped with state-of-the-art LBW machines to meet the stringent quality requirements needed for cryogenic, ultra-high vacuum or radiofrequency applications

Application development expertise

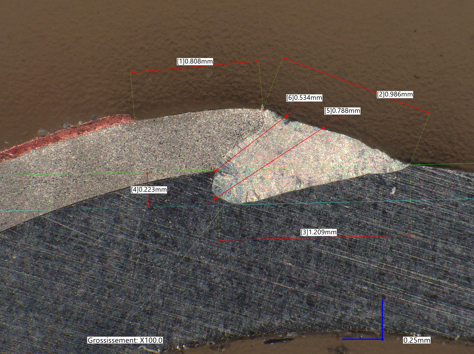

Working in close collaboration with EN-MME metallurgy and NDT teams, we are able to test our welding procedures with a wide range of destructive and non-destructive techniques. This means we are able to quickly develop and qualify procedures for new applications.

Laser Beam Welding at CERN’s main workshop: a long history

LBW technology has been available at CERN’s main workshop for more than 30 years, for the benefit of the accelerator complex and the broader physics community.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Forming and Welding Section can do for you.