Forming

Combining automation and craftsmanship.

Forming at CERN brings together modern equipment and skilled hands, ensuring both repeatability and flexibility in the production of complex, high-performance parts.

Advanced forming techniques for complex, high-performance components

At CERN, forming combines cutting-edge equipment with the craftsmanship of skilled technicians, enabling the production of intricate geometries with both precision and flexibility. From delicate capillaries to large-scale assemblies, forming ensures components meet the demanding standards of accelerator technology.

Bending on press brakes

Beyond straight folds, our press brakes enable precise incremental bending to create tubes, curved profiles, and complex shapes. With a polymer-based tool, we can achieve delicate shaping without damaging or deforming the material in any way.

Precision Tube & Cone Rolling

From straight cylinders to tapered cones, our rolling machines precisely shape metal sheets into a wide range of geometries with tight tolerances, ensuring they are ready for seamless welding, finishing, or final assembly in complex manufacturing processes.

Deep Drawing for Complex Shapes

In deep drawing, sheets are reshaped through extensive plastic flow, where mastering material deformation and stress distribution ensures precise geometry and consistent thickness throughout the part, even when forming demanding contours and complex structural features.

Pipe bending

From millimetre-scale stainless steel capillaries to large aluminium busbars, bending covers the full range of accelerator needs, delivering accurate, repeatable geometries that support reliable integration, optimal performance, and efficient downstream assembly throughout the entire system.

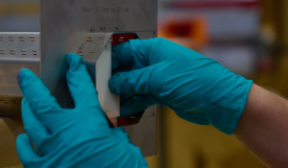

Fine sizing

The final geometry is achieved through the expertise of sheet metal technicians, who fine-tune and verify each shape with practiced skill, applying careful adjustments, precision measurement methods, and craftsmanship that ensure every component meets demanding technical specifications.

Precision Extrusion for RF and UHV

The extrusion of tubes into complex junctions allows full penetration welds and accurate geometry, tailored to the stringent requirements of high-frequency and ultra-high vacuum systems.

Hot metal gas forming of Aluminium Bellows

Using hot nitrogen gas, aluminium tubes are expanded into corrugated bellows with fine wall thickness and UHV-tight performance.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Forming and Welding Section can do for you.