Electron Beam Welding

Welding solutions for demanding applications

Precision, deep-penetration welds minimal heat input and limited distortion.

Precision electron beam welding techniques tailored for CERN’s unique challenges

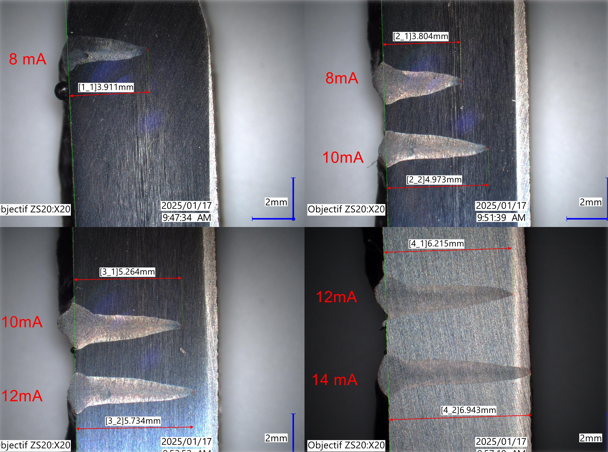

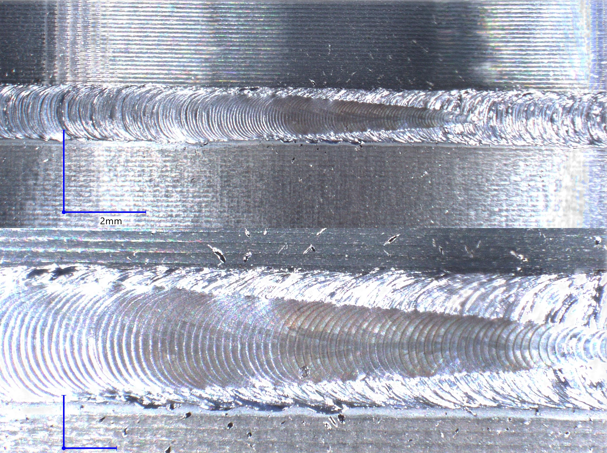

As part of CERN’s advanced joining capabilities, electron-beam welding is selected for applications demanding exceptional precision with minimal distortion, consistent high quality, ultra-clean environments, and the ability to work with exotic or reactive materials. Their penetration depth can be finely controlled, ranging from as little as 0.1 mm to several tens of millimetres, making them suitable for both delicate and large-scale assemblies.

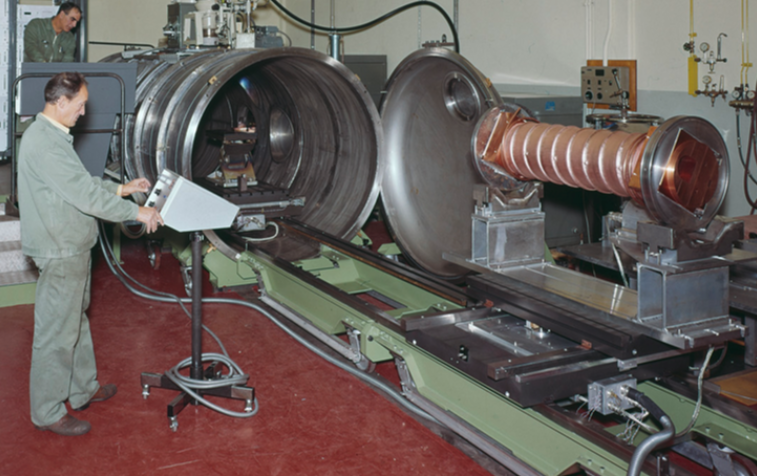

With more than 50 years of experience, CERN has developed and refined these processes, including welding parameter optimization and the design of dedicated fixtures, to meet the demanding requirements of high-energy physics. Applications cover a broad spectrum of critical components such as ultra-high vacuum chambers, radiofrequency cavities, superconducting magnets, cryogenic systems, pressure equipment, and beam-interacting devices.

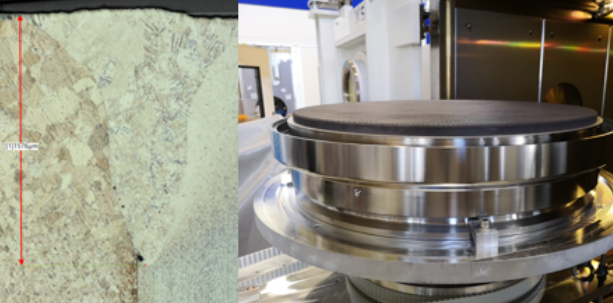

Application development expertise

Working in close collaboration with EN-MME metallurgy and NDT teams, we are able to test our welding procedures with a wide range of destructive and non-destructive techniques. This means we are able to quickly develop and qualify procedures for new applications.

Robust, reproducible welding solutions for a wide spectrum of critical components.

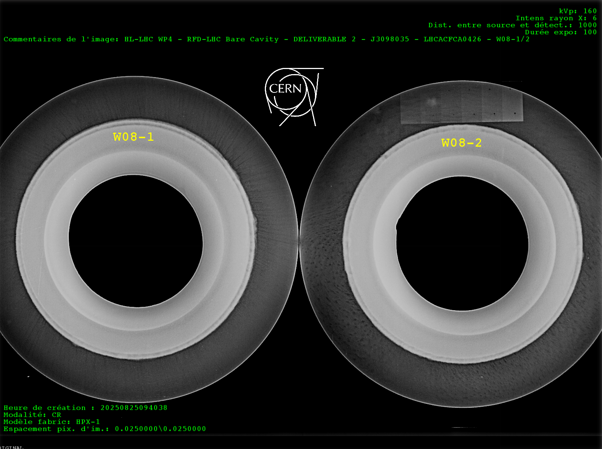

Radio-Frequency

RF and superconducting RF (SRF) can require exotic material combinations, such as copper-to-niobium welding, demanding advanced joining techniques, strict process control, and thorough inspection to guarantee reliable performance under extreme operating conditions

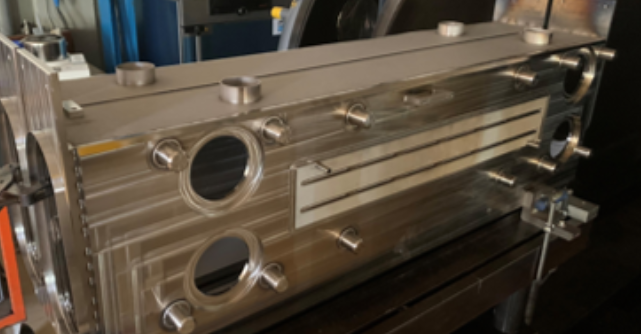

Ultra-High Vacuum

As it operates under vacuum, EB welding is a clean welding process that can be used for welding UHV components, ensuring minimal contamination, exceptional joint integrity, and highly consistent results even in demanding high-performance applications.

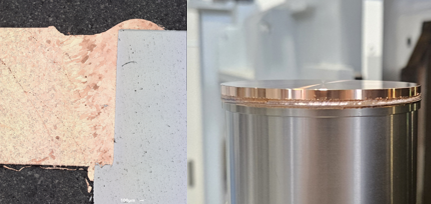

Beam Intercepting Devices

EB welding is involved in the manufacturing of BIDs, such as the precise welding of a thin 1 mm window placed between CFRP disks for LHC beam dumps, ensuring structural integrity and vacuum compatibility.

Pressure Equipment

EB brazing is used to braze high-pressure CO₂ cooling tubes going into the heart of the new HL-LHC detectors, providing leak-tight, robust connections that ensure reliable operation under extreme thermal and mechanical stresses.

EBW at CERN’s main workshop: a long history

The number of components to produce has an influence in the optimal fabrication process. Large series require prototype units to validate the fabrication sequence. Our expertise allows to envision the series production and reproduce the fabrication conditions.

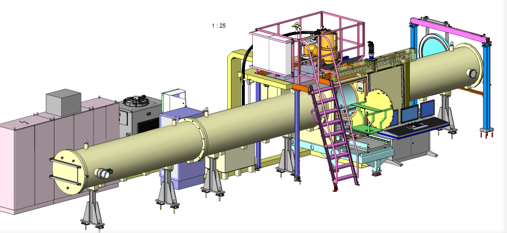

Facilities

Our workshop is equipped with state-of-the-art EBW and LBW machines to meet the stringent quality requirements needed for cryogenic, ultra-high vacuum or radiofrequency applications

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Forming and Welding Section can do for you.