Radio Frequency Components

Forming and Welding RF Dipole Crab Cavities

Overview

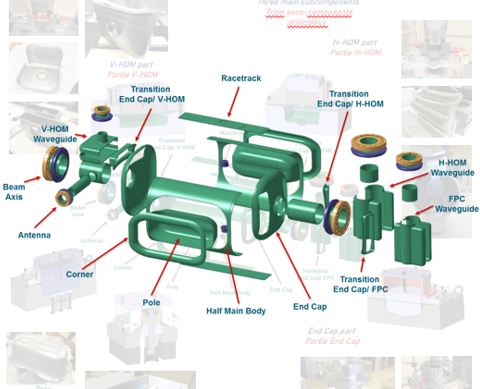

The RF Dipole (RFD) crab cavity, developed for the HL-LHC, tilts the particle bunches to maximise head-on collisions at the interaction points. Each cavity is built from high-purity niobium through precision forming, electron beam welding and vacuum brazing, ensuring exceptional geometric accuracy and superconducting performance.

Forming

All niobium parts of the RFD crab cavity were produced through carefully optimised deep drawing and forming processes to achieve stringent shape accuracy and surface quality. Finite element simulations and Forming Limit Diagram (FLD) analyses were used to predict strain distribution and prevent defects such as thinning or wrinkling. Tooling geometry and lubrication were refined to obtain precise shapes while preserving the initial surface state of the niobium. Special attention was given to avoiding contamination during forming and handling, as cleanliness directly impacts the superconducting performance. This balance between dimensional accuracy, surface integrity, and cleanliness demanded tight control at every step, ensuring that all cavity components met the RF and mechanical tolerances required for high-field operation.

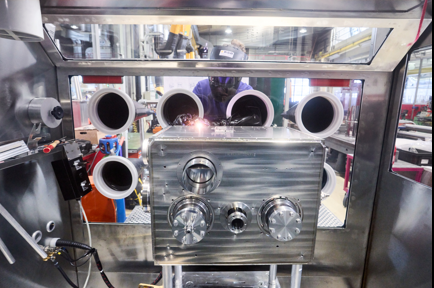

Electron Beam Welding

Due to the strict welding quality requirement required by operation of the cavity with superconducting radiofrequency power at cryogenic temperature, over 10 welding procedure qualification records were established to guarantee the best possible weld quality for all the 40+ welds necessary to assemble a cavity.

In addition, the cavity presents unusual welding paths (other than circular or linear) for which a custom software solution was developed to guarantee the repeatability of the welding parameters.

Vacuum Brazing

Vacuum brazing was used to assemble the ceramic feedthroughs and beam pipe interfaces on the SRF crab cavities. The component geometry had a strong influence on heat distribution and stress development during the process, requiring careful control of temperature profiles and joint design. Optimised heating cycles and filler alloy selection ensured reliable, leak-tight joints between stainless steel, titanium, and copper and ceramic parts, maintaining mechanical stability and vacuum integrity through repeated cryogenic operation.

Validated Manufacturing Approach

The combination of advanced forming, precise electron beam welding, and controlled vacuum brazing ensured the reliable fabrication of RFD crab cavities that meet the stringent mechanical, geometric, and RF specifications of the HL-LHC. Each process was carefully optimized for accuracy, repeatability, and cleanliness, establishing robust methods now applied to series production at CERN and in industry.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Forming and Welding Section can do for you.