Additive Manufacturing

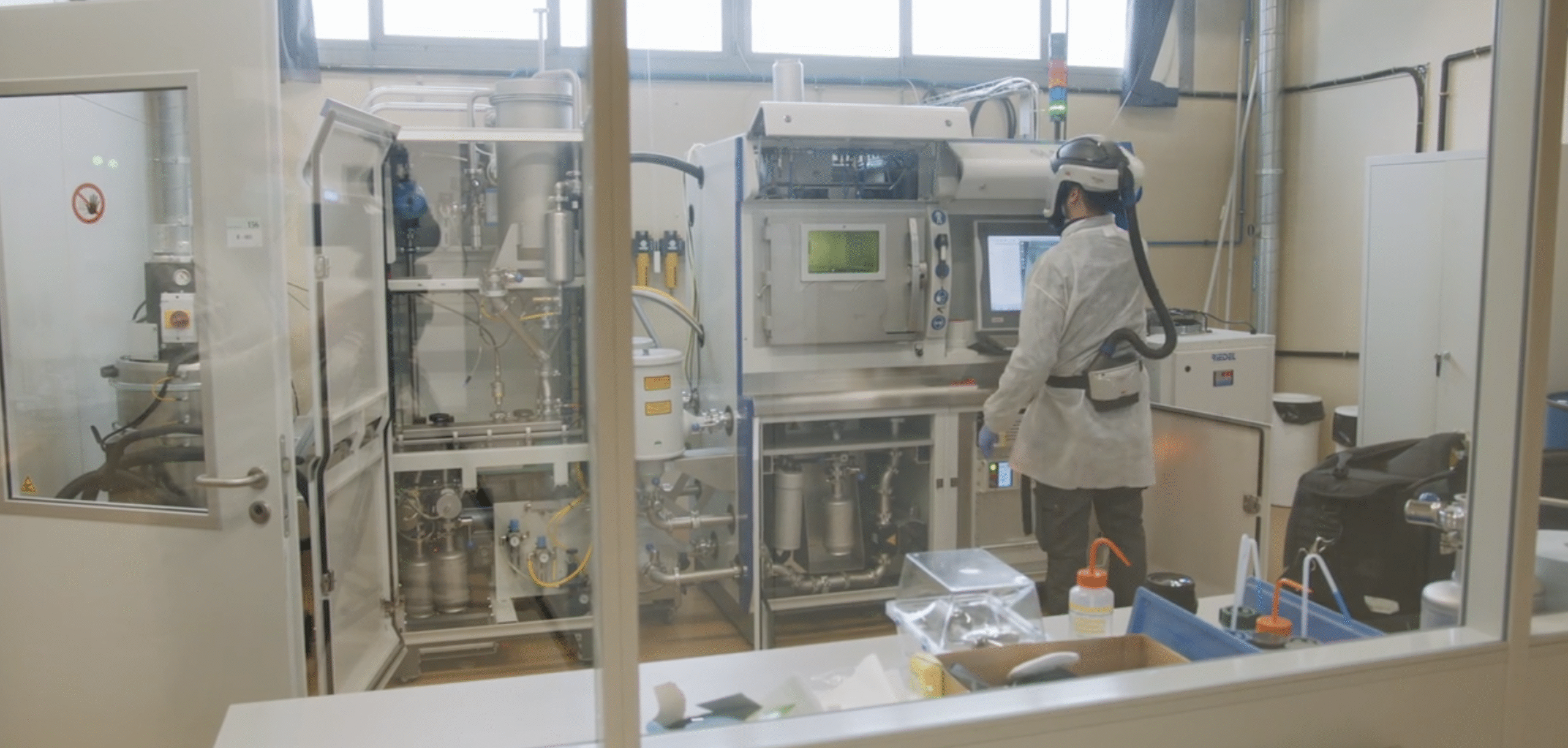

Metal Additive Manufacturing at CERN with Powder Bed Fusion

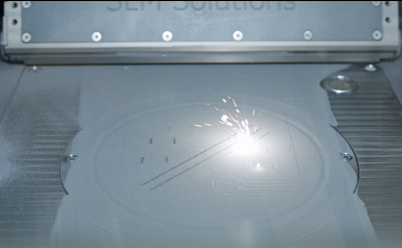

How Powder Bed Fusion Works

Powder Bed Fusion (PBF) is a metal additive manufacturing process where a Laser selectively melts fine layers of metal powder to build a part directly from a digital model. The technique enables lightweight, complex, and high-performance components with minimal material waste—ideal for accelerator applications requiring precision, vacuum compatibility, and integrated cooling.

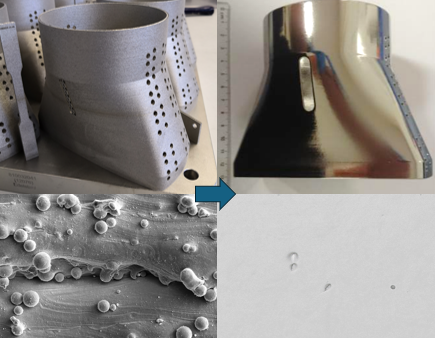

Surface Finishing and Cleanliness

Metal Additive Manufacturing (AM) enables intricate, lightweight parts for accelerators, but surface quality and cleanliness are critical for vacuum and RF applications. CERN developed cleaning, polishing, and inspection workflows to remove trapped powder, reduce roughness, and achieve ultra-high-vacuum compatibility—key for reliable cryogenic and RF performance.

New Materials Development

CERN explores AM with niobium, tantalum and copper to meet the extreme demands of accelerators. Process optimisation and post-processing ensure dense, chemical purity, and leak-tight components. Collaborative Research and Development with industry is advancing qualification for these challenging materials.

Prototyping and Small Series

AM accelerates the design-test cycle and enables small-batch production of complex parts such as RF structures, detector components and Ultra High Vacuum parts. Recent CERN projects demonstrate how innovative design and powder-bed fusion shorten lead times while maintaining precision and performance.

Accelerating Innovation with Powder Bed Fusion

Metal additive manufacturing (AM) creates new opportunities for how accelerator components can be designed and produced. Through powder bed fusion, engineers create complex parts in copper, niobium, titanium, and other advanced materials—achieving lightweight designs, integrated cooling, and improved thermal and RF performance. By mastering surface finishing and cleanliness, CERN has advanced AM from rapid prototyping to reliable small-series production, with qualified components now operating under vacuum and cryogenic conditions across CERN’s accelerator facilities.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Forming and Welding Section can do for you.